Repair vintage speakers effectively by patching tears or cracks in the cone with black silicone sealer. Strengthen the speaker perimeter to prevent distortion and maintain structural integrity.

Use contact cement to enhance durability and sound quality, extending the lifespan of your vintage speakers.

These innovative techniques are essential for ensuring peak functionality and preserving peak audio quality, providing an immersive sound experience that withstands the test of time.

Discover more about the importance of speaker maintenance, the repair process, and the benefits of using contact cement to revitalize your vintage speakers and enjoy high-quality audio for years to come.

Key Takeaways

- Patching tears or cracks with black silicone sealer maintains speaker flexibility.

- Strengthening the speaker perimeter prevents distortion and enhances performance.

- Contact cement creates a durable bond between speaker components for longevity.

- Restoring elasticity in the perimeter edge is crucial for structural integrity.

- Innovative repair methods like using contact cement can significantly extend vintage speaker lifespan.

Importance of Speaker Maintenance

Maintaining vintage speakers is essential for preserving their functionality and ensuring peak audio quality over time. Speaker preservation requires attention to detail and proactive care to prevent degradation.

DIY techniques play an important role in keeping these audio components in excellent condition. Regular inspection of speaker cones for tears or cracks is essential in speaker maintenance. Patching these issues with black silicone sealer can help maintain speaker flexibility.

Additionally, strengthening the speaker perimeter is key to preventing distortion. Using contact cement to restore elasticity and strength to the speaker’s perimeter can greatly enhance its performance and extend its lifespan.

These DIY methods provide cost-effective solutions to maintain vintage speakers and uphold their audio quality for years to come.

Read Also: Fix My Speaker – Remove Water from Speakers in 1 min 14 sec

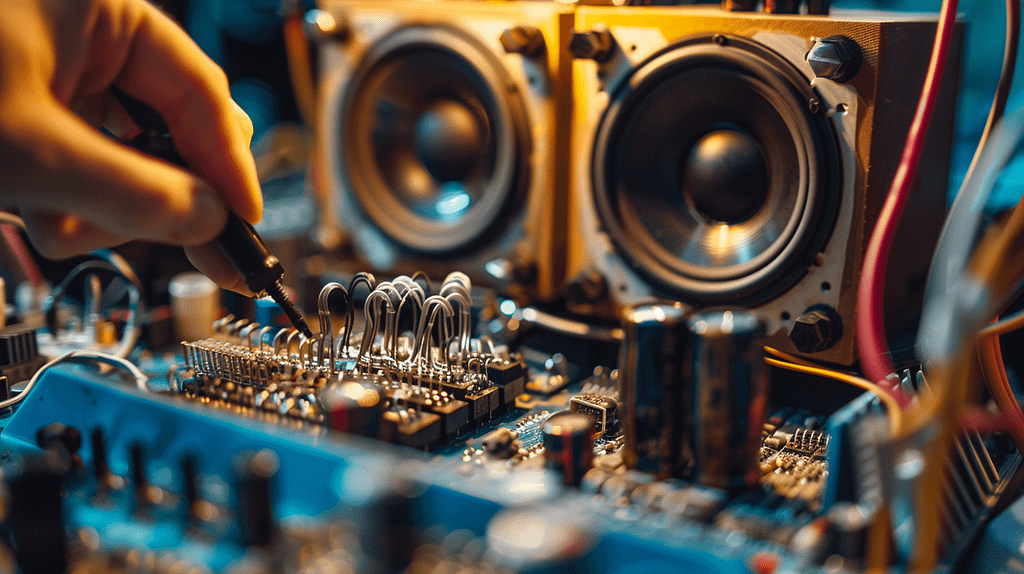

Speaker Repair Process

Identifying tears or cracks in the speaker cone is the initial step in the speaker repair process. Once identified, patching these cracks with black silicone sealer helps maintain flexibility.

Radial cracks, often found in aged speakers, require a light coat of silicone sealer for restoration. To engage the audience further, here is a table showcasing some DIY techniques and preventative measures for speaker cone longevity:

| Speaker Cone Restoration | DIY Techniques | Speaker Cone Longevity | Preventative Measures |

| Patching cracks | Black silicone sealer | Regular maintenance | Avoiding overloading |

| Radial crack repair | Light coat application | Proper storage | Monitoring temperature |

| Flexibility enhancement | Sealer drying time | Gentle handling | Dust protection |

These methods can help extend the life of vintage speakers effectively.

Strengthening the Speaker Perimeter

To fortify the speaker perimeter and prevent distortion, reinforcing the flexibility of the perimeter edge is essential.

Radial cracks indicate weakening of the speaker perimeter, highlighting the need for restoration of elasticity in this area.

Strengthening the perimeter is vital for maintaining the speaker’s structural integrity and ensuring excellent sound quality.

Here are key steps to contemplate:

- Assess the extent of radial cracks for targeted repair.

- Use specialized materials to restore elasticity to the perimeter.

- Apply reinforcement techniques to enhance the flexibility of the edge.

- Ensure thorough coverage of the weakened areas to prevent further distortion.

Benefits of Using Contact Cement

Strengthening the speaker perimeter to prevent distortion is a critical aspect of speaker maintenance, and using contact cement offers substantial benefits in enhancing durability and sound quality. Contact cement provides long-term durability by creating a strong bond between the speaker components, ensuring structural integrity over time.

This adhesive solution is a cost-effective alternative to reconing, saving on expenses while delivering reliable results.

By applying contact cement to reinforce the speaker perimeter, elasticity is restored, minimizing the risk of distortion, especially at high volumes or when playing bass-heavy sounds.

The impact on the speaker’s performance is positive, extending its lifespan significantly. Overall, utilizing contact cement is a practical and efficient way to maintain vintage speakers, ensuring they continue to deliver excellent audio quality.

Frequently Asked Questions

Can Contact Cement Be Used on Any Type of Speaker Material?

Yes, contact cement can be used on various speaker materials. It is a vital option for speaker restoration and maintenance. When exploring alternative methods like contact cement, it is important to take into account the speaker’s material to guarantee compatibility and effectiveness.

How Long Does the Silicone Sealer Take to Dry on Speaker Cracks?

When mending speaker cracks with silicone sealer, drying time varies based on climate. Typically, it takes 24-48 hours to cure fully. Patience is crucial to guarantee the sealer bonds effectively, strengthening the speaker for optimum performance.

Are There Specific Brands of Contact Cement Recommended for Speaker Repair?

I’ve found that for speaker restoration and maintenance, brands like 3M and DAP are often recommended for their durability and effectiveness. These contact cement options provide strength and flexibility important for speaker repair techniques.

What Are the Potential Risks of Using Contact Cement on Speakers?

Using contact cement on speakers poses risks of adhesive compatibility affecting speaker longevity. Improper application may compromise repair technique and impact speaker aesthetics. Careful consideration and technique are essential to mitigate potential damage.

Can Contact Cement Be Used to Repair Other Audio Equipment Besides Speakers?

I’ve found that contact cement can work wonders in repairing various audio equipment. Its versatility in equipment maintenance and repair, coupled with its innovative approach in audio technology, makes it a go-to solution.

Conclusion

To sum up, the utilization of contact cement in revitalizing vintage speakers is a game-changer, offering a cost-effective solution to speaker repair.

By reinforcing the speaker perimeter with this innovative method, we can prolong the lifespan and enhance the performance of these classic audio gems.

So, next time you come across an old speaker in need of some TLC, consider the power of contact cement to bring it back to life and preserve its nostalgic sound for years to come.